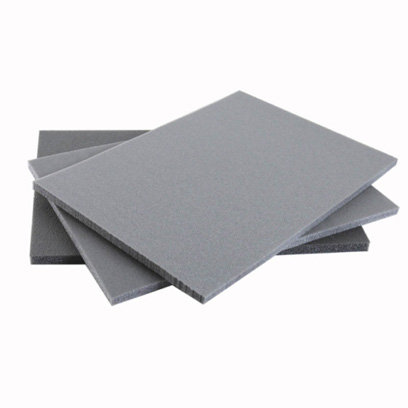

Product size

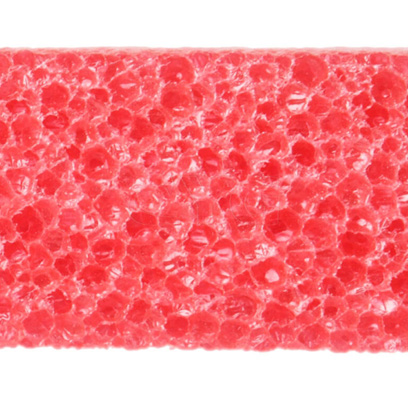

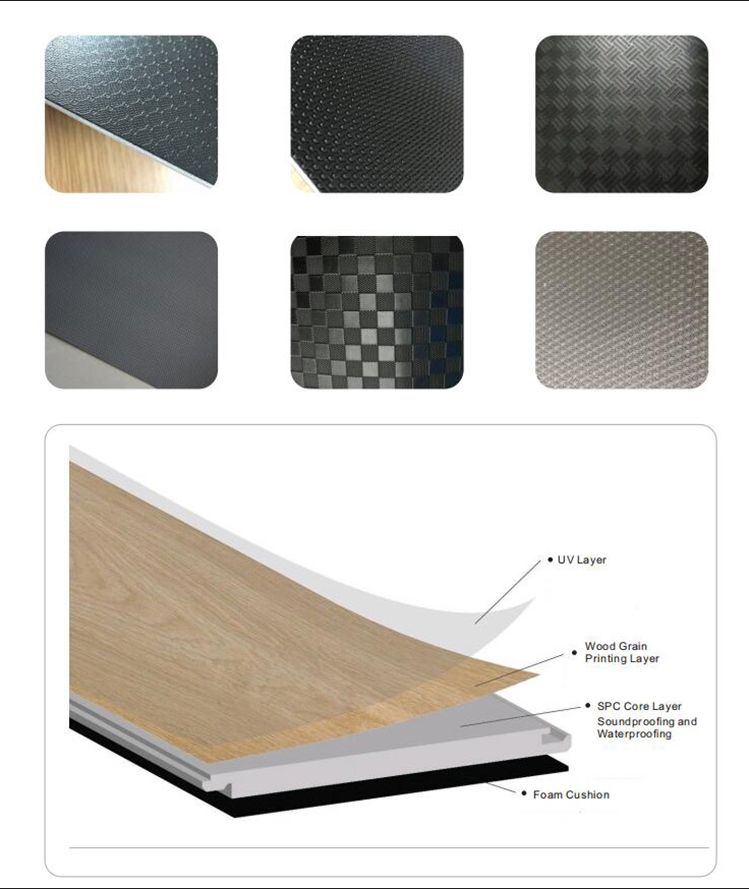

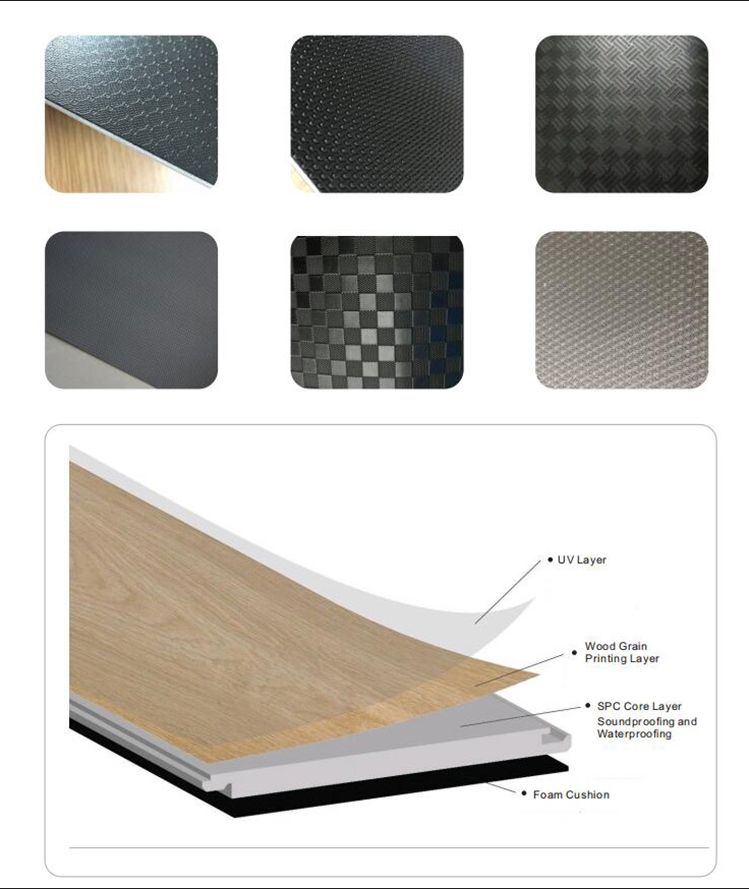

Product name:Irradiated Cross-linked polyethylene foam

Material: LDPE (Low density polyethylene)

Density: 25~330Kg/m^3

Ratio Times: 2~40

Thickness:0.15~15mm (single layer) to 80mm (multilayer)

Width: 600~2400mm

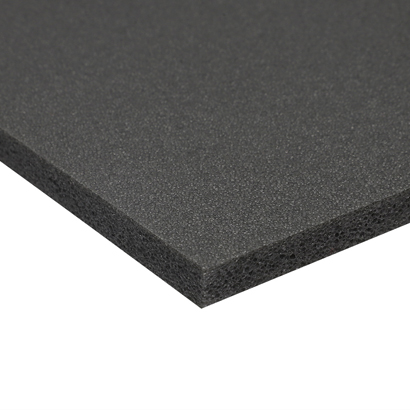

Color: Black, White, Grey or customized

Shore hardness: 15~65°(≤3mm)13~70°(>3mm)

Thermal conductivity: 0.038~0.095w/m.k

Working temperature (-40℃~80℃, up to 120℃ for special specifications)

Flame retardant: Support customization

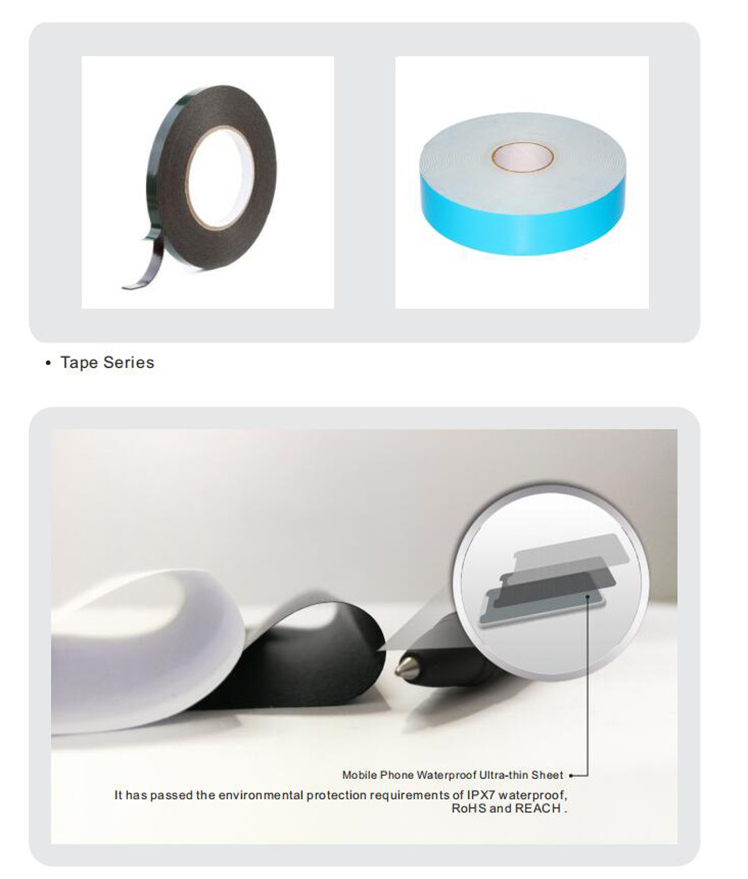

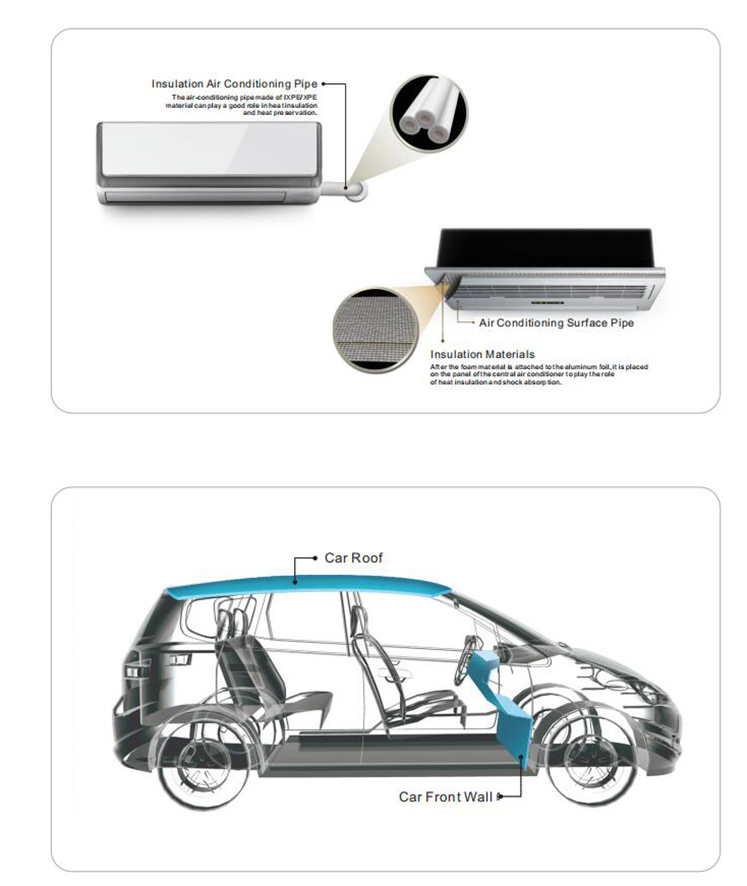

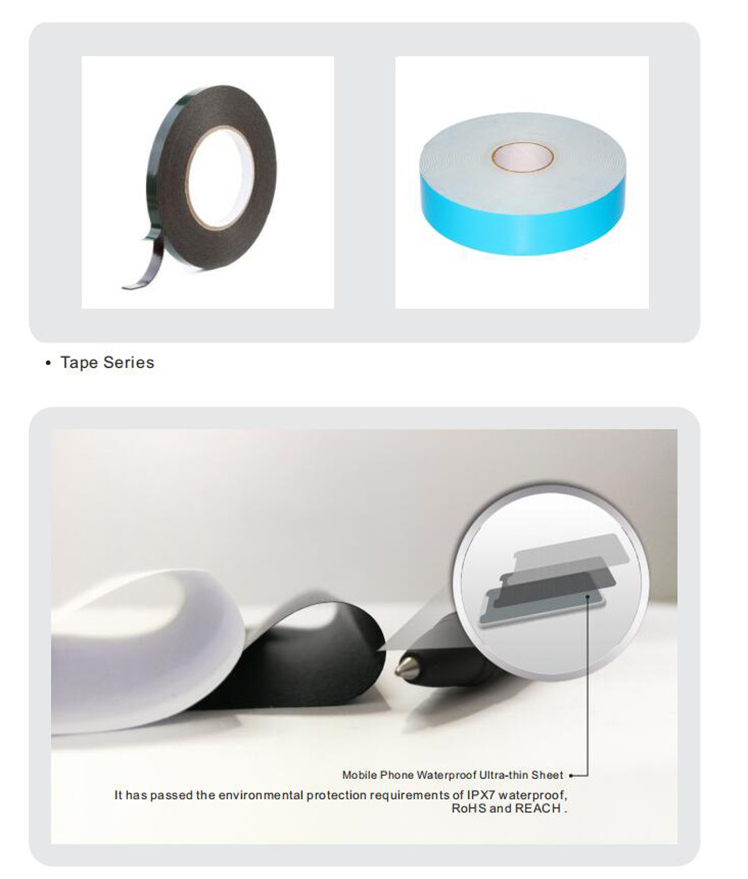

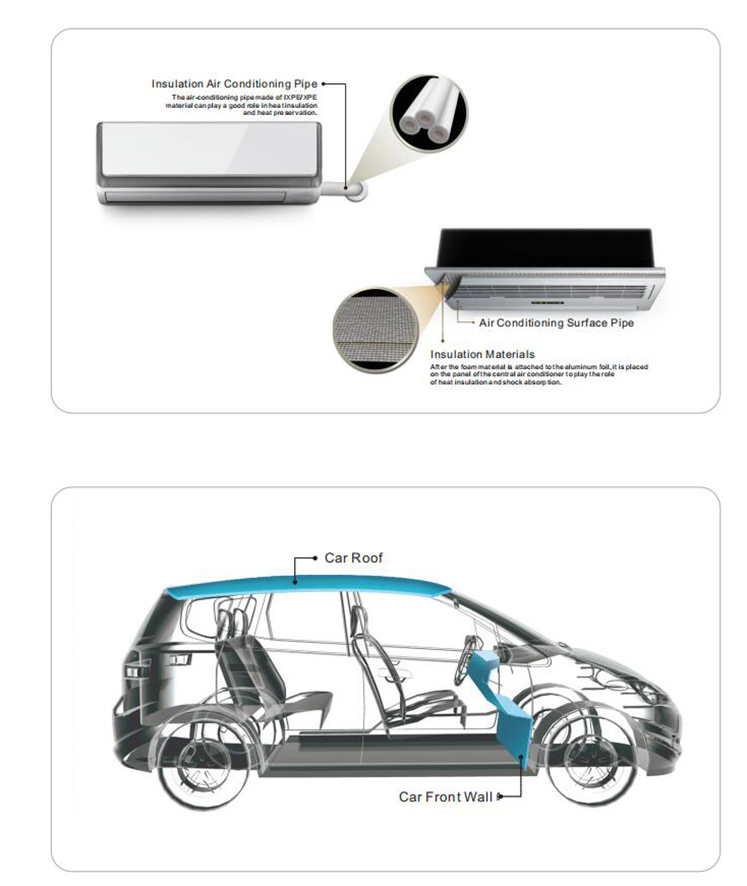

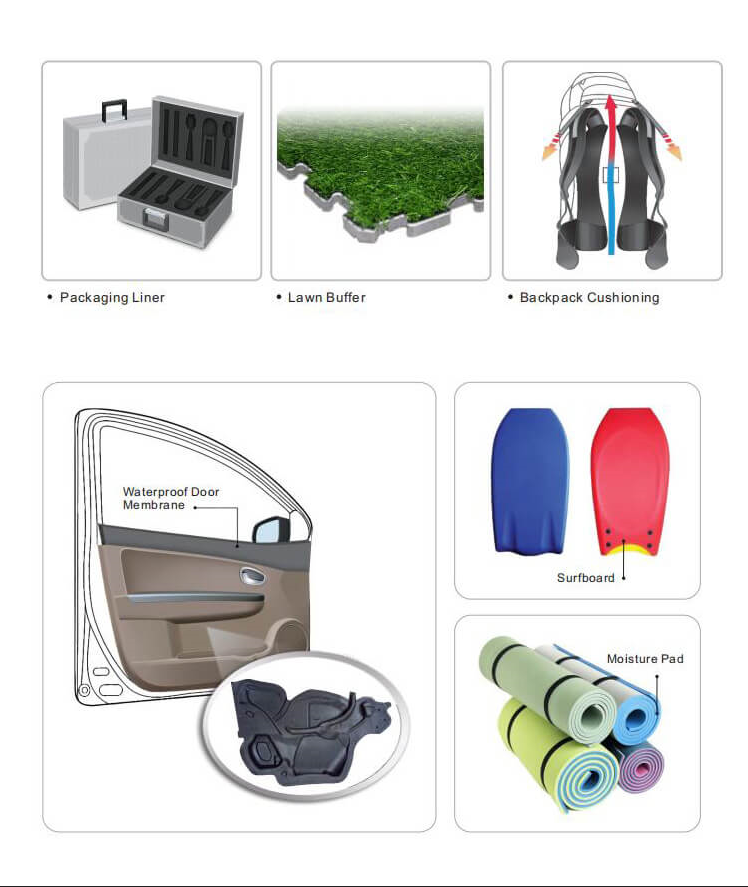

Function: Thermal insulation, Waterproof and Sound insulation

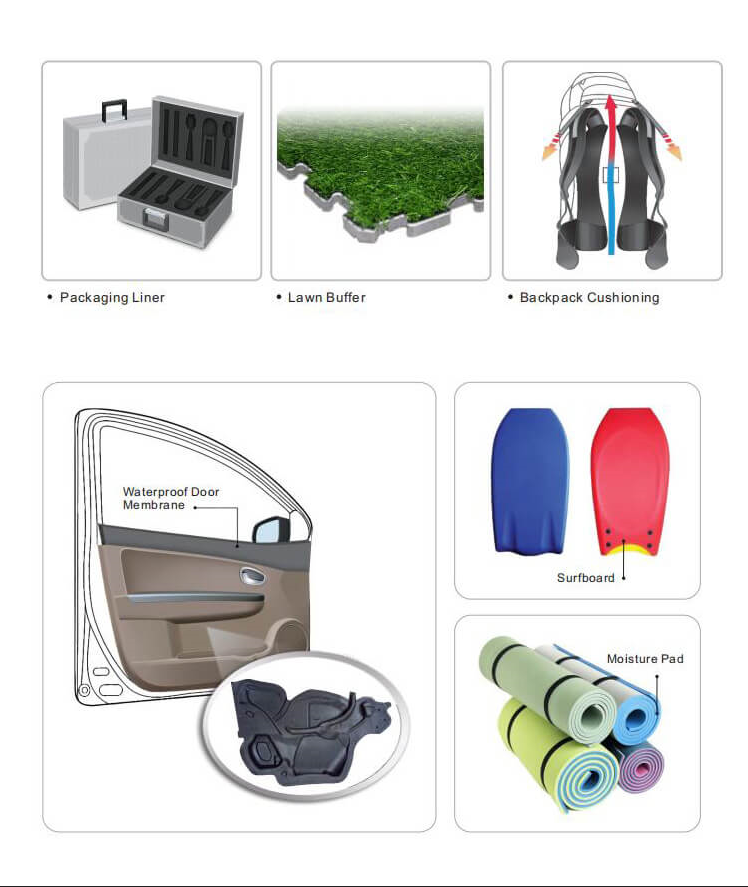

Application: HVAC& Air conditioner, Automotive, Building and Construction, Sports & Leisure etc.

Certificate: SGS CE Reach UL etc.

Vertical IXPE: 0.15mm~3mm foam

FAQ

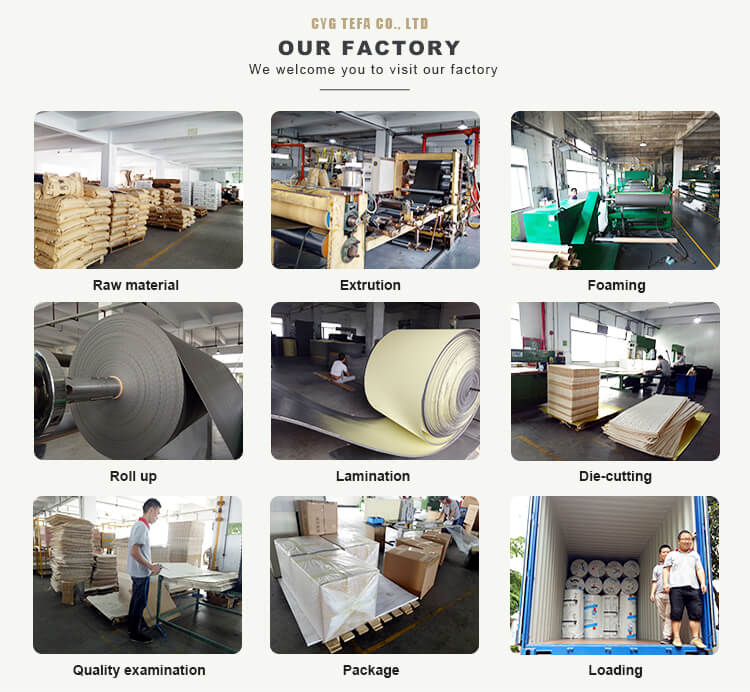

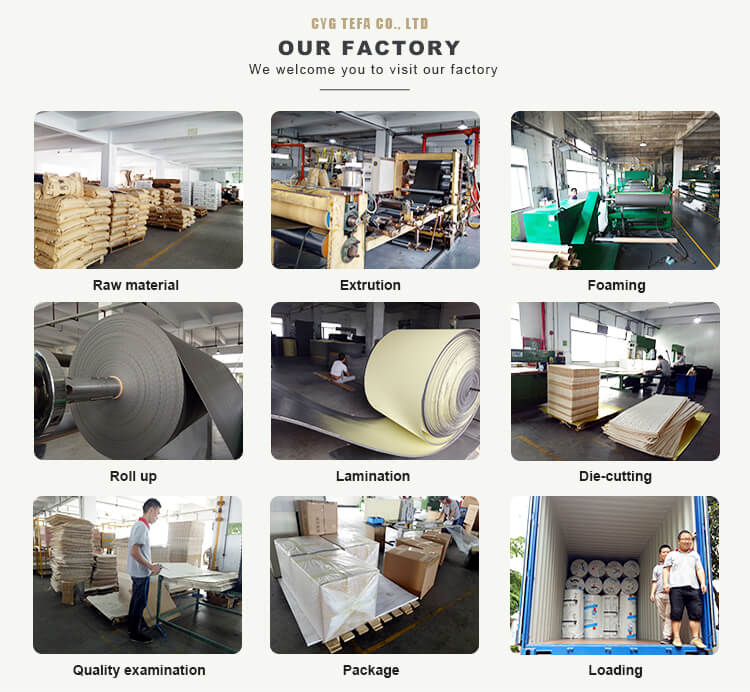

1:Company information?—CYG TEFA Co., Ltd We’re the biggest and the most professional irradiation crosslinked polyethylene conductive foam manufacturer in China and has the most complete crosslinked polyethylene foam products. Our main products are Crosslinked PE foam material, IXPE foam, XPE foam, Conductive IXPE foam; ESD foam tray, Foam packing material; Building insulation material; Flooring underlayment; Camping mat, Tent sleeping mat; Etc. Now, we have 2 factories and 50 production lines.

2:Can we distributor your product? —Yes, you are warmly welcomed to be our distributor.

3:What’s your warranty policy? —We provide 12-Months warranty on all of our products, which means during the warranty period, we’ll repair the defective items or other solutionsif with quality problems.

4:Why choose you? —Foam Form Sheet, Roll, and Pad Thickness Single layer 0.15-15mm, Max 80mm Width 1-1.6meter Can Be Cut By Customers’ Requirement.Packaging Polybag Lead Time 3 Days For Sampling, 15 Days For Production.MOQ No MOQ For Stock, 1000 Meter For Customized Product.

5:How Can I order? —You can send us inquiry by email or whatsapp— Input quantity, your country, The final price and shipping cost are subject to our sales quotation.

6: When could I get the quotation? —We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email.

7: How about the delivery cost and tax cost? —Delivery cost is depend on the way, destination and weight. And tax is depend on customer’s local customs.